Overview

Qualimark employed its expertise and experience in designing and developing world’s most successful Automatic Chapati Making Machine. Developed after thorough research and by following an innovative design approach, the automatic chapati making machine is a compact, energy-efficient and high-performance machine that speeds up the food preparation process. The machine works on Three conveyor and 360-degree chapati baking technology, advanced precision motor and gearbox that promises high rate of production with optimum chapati cooking/roasting and least maintenance. Also, the machine offers better insulation owing to superior-grade heating components.

Precision-engineered product with Unique Features

Three conveyor Technology

360° Chapati Baking

Unibody Concept

Smallest Chapati Making Machine

Travel Friendly Machine Ideal for Hotels and Caterers

Up to 50% gas Saving

Up to 50% Electricity Saving

Less Maintenance

In house Designed Burners

Easy to Clean

India’s Most Compact Chapati Machine

India’s Most Compact Chapati Machine

Qualimark has launched first-of-its-kind automatic chapati machine that boast of being the smallest chapati making machine in India. With great aesthetics, compact size and less weight, it is completely different from other machines available in the market. Designed brilliantly by the experts at Qualimark’s R&D centre, the machine just weighs 150 kg and is 3.93 ft long. The machine is extremely easy to transport and requires low maintenance. Also, owing to compact size, the machine requires minimal space for operations.

Travel Friendly Machine & Ideal for Hotels and Caterers

Travel Friendly Machine & Ideal for Hotels and Caterers

The machine is quite travel friendly which enables caterers, hotels and restaurant users to take machine from one place to another place with ease. The machine is very much light in weight and Compaq in size thus easily movable and can be used anywhere even to the remotest location. The machine can fit even in very less space. These features and qualities make it ideal for hotels, restaurants and caterers where space is scars and mobility is required.

360° Chapati Baking

360° Chapati Baking

Existing chapati making machine design just focus on heating chapati from only two sides, making 1/3 part of chapati devoid of proper heat for baking. This leads of undercooked chapatis as burners only heat chapati from the top and bottom. Qualimark’s unique 360˙ baking process- developed in-house ensures that heat spreads equally in the machine from all sides. The burners working on this process ensure perfectly roasted chapatis from all the sides, improving the overall quality of chapati.

Less Maintenance

Less Maintenance

Qualimark’s automatic chapati machine is extremely compact with fewer rotational parts compared to existing machines. This makes it easier to operate, clean and maintain. As the machine consists of very less number of moving parts, it also promises minimal noise and vibration during operations. With 50% less burners and electric parts and only one conveyor compared to three in conventional machines, the machine requires very less maintenance during the course of operations.

Automatic Chapati Machine Three Conveyor – ACM5-3C

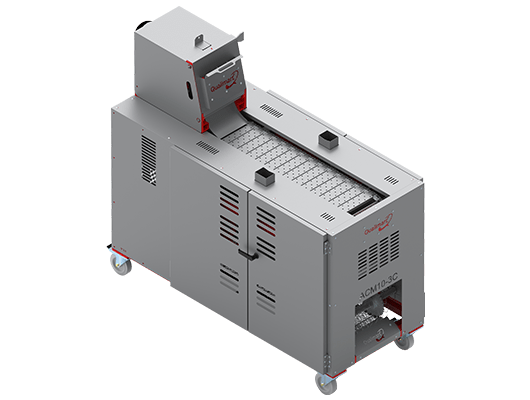

Automatic Chapati Machine Three Conveyor – ACM10-3C

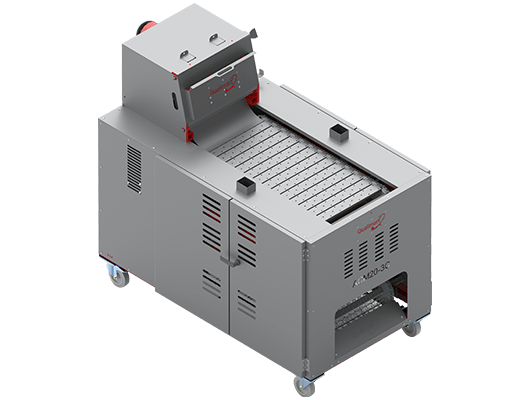

Automatic Chapati Machine Three Conveyor – ACM20-3C

Technical Specification

-

- Type

ACM5-3C

ACM5-3C ACM10-3C

ACM10-3C ACM20-3C

ACM20-3C

-

- Production Rate (Approx.)

- 500 Nos. / Hr.

- 1000 Nos. / Hr.

- 2000 Nos. / Hr.

-

- Weight of Chapati

- 15 to 60 Gms.

- 15 to 60 Gms.

- 15 to 60 Gms.

-

- Thickness of Chapati

- 1.2 to 3 mm

- 1.2 to 3 mm

- 1.2 to 3 mm

-

- Size of Chapati

- ø 3″ to ø 7.5″

- ø 3″ to ø 7.5″

- ø 3″ to ø 7.5″

-

- Required Elec. Power (HP / kW) 1Phase

- 5.33 HP / 3.97 kW

- 5.87 HP / 4.35 kW

- 10.67 HP / 7.95 kW

-

- Gas Pressure

- 7 psi.

- 7 psi.

- 7 psi.

-

- Gas Consumption

- 0.8 – 1 Kg / Hr.

- 1.5 – 2 Kg / Hr.

- 3.5 – 4 Kg / Hr.

-

- Weight (Kg.) Approx.

- 260

- 355

- 420

-

- Overall Dimensions (Ft.)

- 4.8 x 2.6 x 5.2 (L x W x H)

- 5.5 x 2.6 x 5.2 (L x W x H)

- 5.5 x 3.4 x 5.2 (L x W x H)