Overview

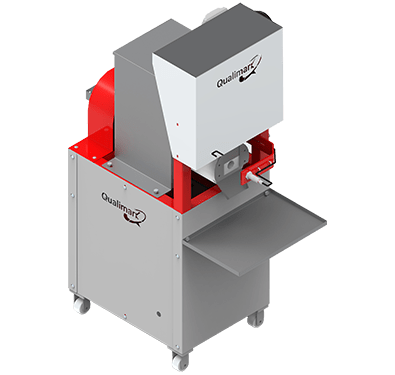

Dough ball making machine by Qualimark is a highly sought after product in food processing industry that fastens up the process of making dough for chapati, poori and other flat bread in bulk. The machine is easy-to-operate and clean and can be customized to control the size of dough balls as per the requirement. With smooth dough ball cutting and easy-to-integrate mechanism, the machine promises a great boost in productivity of existing operations without hampering current processes. Developed, designed, engineered and produced using high-grade raw materials and latest technology, the machine is an efficient, durable and functional product, essential for every commercial kitchen.

The dough ball making machine can be easily integrated to other machines like Qualimark’s Khakhra making and chapati making machines. This helps the operator in getting rid of the hassle of dough ball making. Also, the machine is made from precision and premium PP material worm that homogeneously mixes the kneaded flour for best-quality dough balls.

Precision-engineered product with Unique Features

Worm Made of Food Grade Material

Easy Dough Ball Size Adjustment

Easy to integrate with other machines

Smooth & Precise Dough Ball Cutting

Very Compact Machine

Easy to Clean

Convenient dough ball size adjustment

Convenient dough ball size adjustment

The machine comes with a user-friendly mechanism to adjust the weight and size of the dough ball. A precise non-contact photovoltaic sensor-based system is used in the machine’s mechanism that facilitates dough ball size adjustment. The feature makes it easier for even a layman without any sill to adjust the dough ball size as required.

Easy integration with other machines

Easy integration with other machines

The machine is designed and developed in a way making it easier for the user to integrate the machine into the current system or with other machines such as Qualimark’s Khakhra Making Machine or Chapati making machine.

Being the biggest USP of this product, the integration feature ensures integration into the existing system and getting rid of manual dough ball making process in seconds. There can be significant savings in time and efforts by integrating the machine in current system and the machine can also be customized as per other machines.

Advantages

- Highly-efficient dough ball making machine with easy-to-use and convenient features

- User-friendly settings and features to control the size and weight of dough balls

- Compact size promising less floor space requirement for installation and operations

- High-quality structure manufactured using superior grade raw materials requiring low maintenance

Dough Ball Making Machine

Technical Specification

-

- Type

DB10E

DB10E DB20E

DB20E

-

- Capacity

- Up to 1000 Nos. / Hr

- Up to 2000 Nos. / Hr

-

- Dough Ball Weight

- 20 to 60 Gms.

- 20 to 60 Gms.

-

- Required Elec. Power (HP / kW) 1Phase

- 0.75 HP / 0.55 kW

- 0.75 HP / 0.55 kW

-

- Dough Ball Cutting Technology

- Electric Motor with Blade Technology

(Pneumatic Version is also available)

-

- Overall Dimensions (Ft.)

- 2.70 x 1.40 x 5.40 (L x W x H)

-

- Weight (Kg.) Approx.

- 145