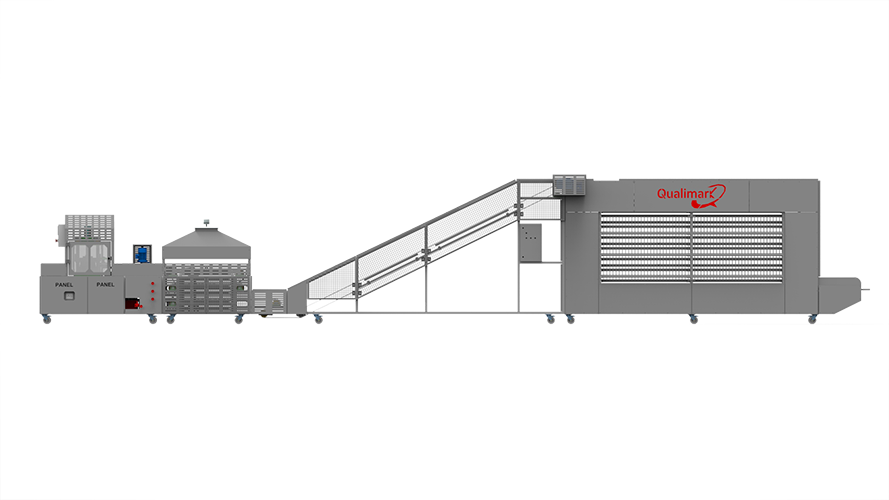

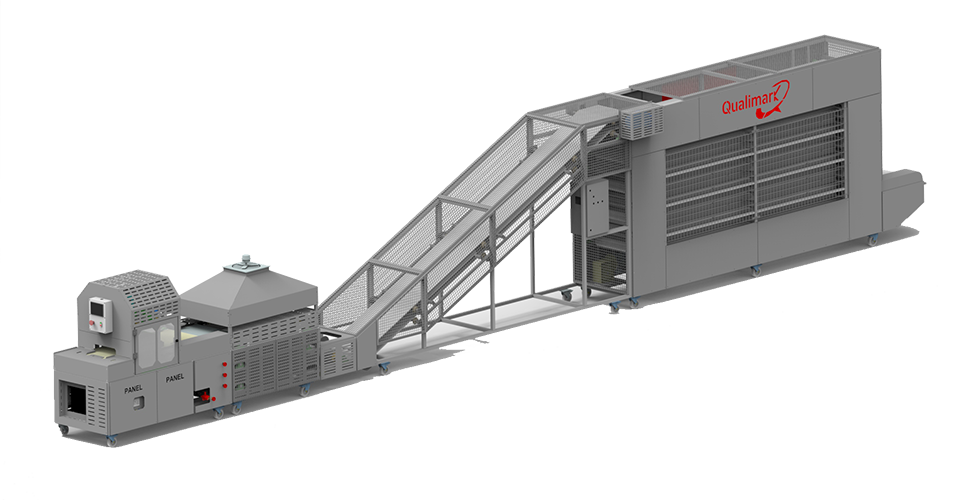

Fully Automatic Flat Bread Production Line

Overview

Qualimark employed its expertise and experience in designing and developing world’s most successful Automatic Chapati Making Machine. Developed after thorough research and by following an innovative design approach, the automatic chapati making machine is a compact, energy-efficient and high-performance machine that speeds up the food preparation process. The machine works on Three conveyor and 360-degree chapati baking technology, advanced precision motor and gearbox that promises high rate of production with optimum chapati cooking/roasting and least maintenance. Also, the machine offers better insulation owing to superior-grade heating components.

Precision-engineered product with Unique Features

Fully Costomizable As Per Customer Need

End To End Solution

Suitable For Multi Product

Higher Product Capacity machine

360° Chapati Baking

360° Chapati Baking

Existing chapati making machine design just focus on heating chapati from only two sides, making 1/3 part of chapati devoid of proper heat for baking. This leads of undercooked chapatis as burners only heat chapati from the top and bottom. Qualimark’s unique 360˙ baking process- developed in-house ensures that heat spreads equally in the machine from all sides. The burners working on this process ensure perfectly roasted chapatis from all the sides, improving the overall quality of chapati.

Less Maintenance

Less Maintenance

Qualimark’s automatic chapati machine is extremely compact with fewer rotational parts compared to existing machines. This makes it easier to operate, clean and maintain. As the machine consists of very less number of moving parts, it also promises minimal noise and vibration during operations. With 50% less burners and electric parts and only one conveyor compared to three in conventional machines, the machine requires very less maintenance during the course of operations.

Technical Specification

-

- Type

Doughball Making Unit

Doughball Making Unit

-

- Production Capacity

- Upto 5000 / Hr.

-

- Doughball Weight

- 20 – 125 Gm

-

- Doughball Cutting Technology

- Electric / Pneumatic

-

- Variable Spee Option

- Yes

-

- Suitable Material

- Wheat / Refined /Wheat (Maida) / Corn /Mixed Flour

-

- Type

Pressing Unit

Pressing Unit

-

- Production Capacity

- Upto 5000 / Hr.

-

- Chapati Weight

- 20 – 125 Gm

-

- Chapati Thickness

- 1 – 5 mm

-

- Chapati Diameter

- Upto 12″

-

- Pressing technology

-

Hydraulic / Pneumahc / Mechanical

-

- Humbers of Punches

- 1/2/4

-

- Hot Prass Optien

-

Yes

-

- Type

Roasting Unit

Roasting Unit Transfer Conveyor

Transfer Conveyor

-

- Conveyor Technology

- Three Conveyor

- Single Conveyor

-

- Material Type

- SS304

- SS304 / Rubber

-

- Variable Speed Option

- Yes

- Yes

-

- Heating Technology

- Gas

-

- Auto Ignition Option

- Yes

-

- Gas Safety Option

- Yes

-

- Type

Cooling Conveyor

Cooling Conveyor

-

- Conveyor Technology

- Multi Conveyor

-

- Material Type

- SS304

-

- Number of Conveyor

- 3/5/7/9/11

-

- Variable Spee Option

- Yes

-

- Forced Cooling Option

- Yes

-

- Type

Staking Unit

Staking Unit

-

- No. of Collection Unit

- 2

-

- Technology

- Motor Based

-

- Counting Option

- Yes

-

Note: All Above Technical Specifications Are Customizable As Per Need. Final Size, Weight And Capacity Are Subject To Exact Requirement Of the Customer. Suitable Food Products: Chapati (Un /Semi / Fully Cooked) / TortilIa / Plain Paratha (Round) / Stuff paratha (Round) / Thepla / Puran Poli / Puri